Instant piping technology

- For Compressed Air(Using Aluminum pipe : Size 12 mm – 28 mm)

- For Industrial Grade Water / Coolant / Light Oil (Using Nylon pipe : Size 15 mm)

- For Drinking Water / Food Grade applications(using LLDPE tube : Size 12mm – 15 mm)

| Reason for PRESSURE DROP in pipes |

| Internal Cleanliness |

Flow: Turbulent vs Laminar |

Internal Diameter Variation |

Leakages |

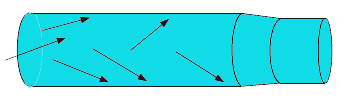

TURBULENT FLOW: In GI pipe

|

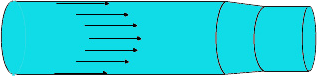

FULL FLOW LAMINAR FLOW: Al / Nylon Pipe

|

A drop of 1 bar pressure in a pipe line results in power losses of over 10%

Annual costs for a 200m system

Benefits of installing

- Smooth bore aluminium / Nylon Pipe

- Consistent internal diameter

- Drop lines integral with Water Trap system

- Rapid fit/modification

Further Benefits

- Reduction in labor in installation

- Easily modified pipe layouts

- Leak free air systems

- Energy efficiency

- No pipe corrosion

- In short, a system with a lower overall cost of ownership.

Benefits when you modify

- Modifications to system (adding drops) can be expensive

- Time consuming

- Production downtime

- Overtime labor

- New systems increase ease of modification

- Drops can be installed in 10 minutes instead of 2 hours

Air leaks – Detrimental to your companies health

| Leak Size |

Loss (CFM) |

Loss (INR/Day) |

Loss

(INR/Year) |

| 0.5mm |

576 |

6.37 |

2352.00 |

| 1.5mm |

9,288 |

99.96 |

36456.00 |

| 3mm |

37,152 |

400.33 |

146069.00 |

| 5mm |

83,952 |

905.03 |

330162.00 |

| Based on Air pressure at 100 psig |

FLOW RATES at your finger tips

| Length |

65 |

130 |

325 |

650 |

1000 |

1300 |

1650 |

3300 |

4900 |

6600 |

ft |

| Air Flow |

20 |

40 |

100 |

200 |

300 |

400 |

500 |

1000 |

1500 |

2000 |

m |

| 10 |

167 |

5 |

18.0 |

18.0 |

18.0 |

18.0 |

18.0 |

18.0 |

18.0 |

18.0 |

18.0 |

18.0 |

|

| 30 |

500 |

20 |

18.0 |

18.0 |

18.0 |

28 |

28 |

28 |

28 |

28 |

28 |

28 |

| 50 |

833 |

30 |

18.0 |

18.0 |

28 |

28 |

28 |

28 |

28 |

28 |

28 |

|

| 100 |

1667 |

60 |

18.0 |

28 |

28 |

28 |

28 |

28 |

|

|

|

|

| 200 |

3333 |

120 |

28 |

28 |

28 |

|

|

|

|

|

|

|

| 300 |

5000 |

180 |

28 |

28 |

|

|

|

|

|

|

|

|

| 400 |

6667 |

235 |

28 |

|

|

|

|

|

|

|

|

|

| m3/h |

I/min |

cfm |

|

|

|

|

|

|

|

|

|

|

This table illustrates the maximum air flow capacity for the 3 size ranges of JOHN GUEST based on an operating pressure of 115 PSI and a maximum pressure drop of 5% over the system.

For e.g. : A 100 metre long pipe line is required to convey a flow of 120 cfm at 115 psi. So the suitable pipe will be 28 mm. For smaller sizes consult factory for flow rates

|